This article is a contribution by yooongchun on Craftwork.com, using bamboo sticks to make a model of the Eiffel Tower. There are so many steps, so many pictures, and it’s so slow to open. It took Xiaolin an entire afternoon to complete it, and I burst into tears┭┮﹏┭┮! Anyway, I’m very happy to be able to share such a good handmade tutorial with everyone. I hope you guys can We all also like yooongchun’s works~

I recently saw a few Eiffel Tower works made by master craftsmen on the Internet. They are very beautiful. I happened to have some free time at night recently and wanted to make one myself. Looking at the works they have made, some use bamboo sticks, toothpicks, and paper clips, but most of them are bamboo sticks and bamboo products. In this way, the threshold for DIY is extremely low, and the required tools and materials are all easily available. of.

Don’t talk much, just do what you say.

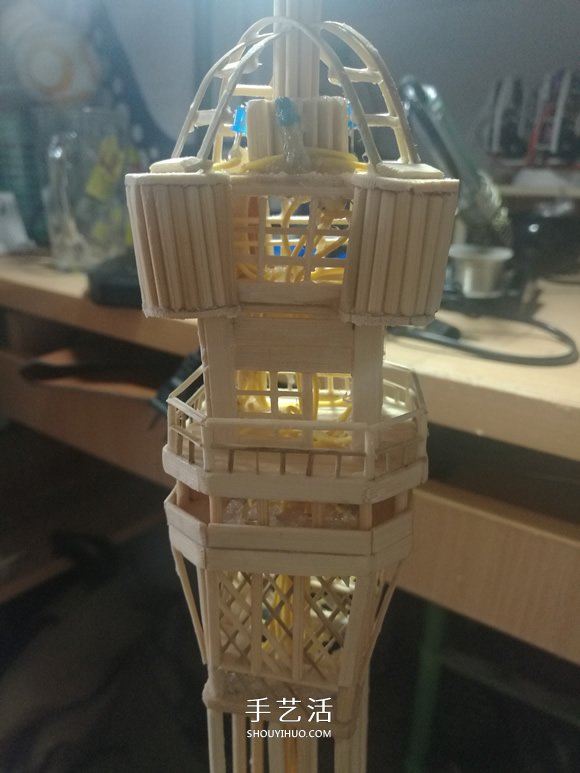

Here are some pictures of the completed work:

Note: Some parts of the production process referred to the tutorials of laoshupi1213, the author of Handicraft Live. I would like to thank the author! , you can find this author’s work at this link!

Okay, the tutorial officially begins!

[DAY-01||2017-07-15] Formulate plans, budgets and purchase raw materials and preparation tools

1. Plan:

The author is a casual person. He usually does things as he thinks of them without any detailed plan. The basis for the early stage is a rough size diagram. He also bought a small model of the Eiffel Tower, and then based on what was mentioned above. The authors work forms, modifies and improves the plan as he works.

2. Budget:

As for the budget, you mainly need to buy tools and bamboo sticks, which is a conservative estimate of 300 RMB. Of course, it mainly depends on the tools you buy. The author is an engineering man and likes tinkering, so he usually has many small tools that need to be purchased. not many.

3. Purchase tools:

It is said that if a worker wants to do his job well, he must first sharpen his tools. If you want to have fun and have fun, a set of handy tools is indispensable. Tools for personal use include but are not limited to the following:

UHU universal glue, about 5 bottles; 502 glue, 10 bottles; several drip tubes; white latex, about one bottle

More than one utility knife (a sharp tool for cutting bamboo skewers, necessary, you can also use any alternative knife)

One or more tweezers. Some parts are very small, or the bonding locations are tricky, so a handy pair of tweezers is essential

A ruler. Used to measure length, essential, you can also use other measurable equipment instead

Cut a branch. Used to cut bamboo sticks. You can use a knife to cut this, but it is highly recommended. It is an essential tool for high efficiency

A pen knife

2-3 sheets of sandpaper for polishing. Used to polish uneven or uneven areas.

File. It has the same effect as sandpaper, but the file can handle more severe conditions

Small plane. Used to smoothen the floor when laying it

A pair of scissors

?

Welding. If you want to install an LED lighting system, you need to solder the circuit

Hot melt glue gun. This has the same function as glue, except that when bonding circuit lines and LED lights, a hot melt glue gun is easier to use than glue

Small drill bit. You can use an electric drill or a hand drill to drill holes

A multimeter. Dispensable

?

A small hand saw. Optional

?

1mm thick wire is about 10m

?

Some rubber bands, small clips, and thumbtacks

?

One A3 cutting mat and one Eiffel Tower model

?

4. Purchase raw materials

4mm diameter bamboo sticks, 500 pieces. In reality, you may not use so much, and the excess will be used as a backup. Mainly used as the main framework

500 bamboo sticks of 2.5mm or 2mm diameter. Used as a framework detail to build

100 pieces of 4mm square bamboo sticks. This is actually not necessary, but it will be easier to bond in some parts if you use a square shape

5mm wide, about 1mm thick, 1000mm long, 20 bamboo pieces. Used to build details, build floors, etc.

?

LED lights

3mm white hair and yellow [1.5--2V] 50 pieces

3mm blue hair [2.5--3V] 100 pieces

?

One USB interface, used as a power input port (if there is one in the ready-made device, it can be removed from it, such as an old mobile phone, etc.)

A power bank for power supply

You can purchase the above tools as needed, and many of them are not necessary. I listed them all because I already have them and can use them!

Okay, let’s go here today. Basically, we have prepared the tools we need. There are still some things that need to be used, so you can buy them when needed!

【DAY-02||2017-07-16】Building the base

1. Make feet

Step 1: Make the foot frame

Cut 16 bamboo sticks with a length of 69mm and a diameter of 4mm, then cut a 45° bevel, then place them in a square position according to the grid on the A3 cutting mat, glue them together, and wait for them to stick Remove after connecting firmly, as shown below

Step 2: Fill the feet

Still using bamboo sticks with a diameter of 4mm, cut out about 15*4 bamboo sticks according to the corresponding length (adjust according to your actual situation), then fill them into the frame made above, and glue them firmly

Step 3: Make the second layer of the foot

The process is the same as before, except that the cutting size is now 58mm in length and 4mm in diameter, a total of 16 pieces, and then bonded to shape

Wait until the glue is basically dry before sticking it to the first layer

Step 4: Use toothpicks for hemming

Use toothpicks or bamboo skewers with a diameter of 2.5mm to wrap the edges at the junction of the first layer and the second layer

2. Make a layer of framework

Step 1: Make the outer frame

First use tree branch shears to cut out a square with a length of 230mm and a side length of 4mm (Note: It is best to use square bamboo sticks here. If you don’t have one, you can also use round ones. ) 4 bamboo skewers, cut out a 45-degree bevel and then glue them according to the grid on the A3 cutting mat to make sure they are square when bonding, and then use thumbtacks to position them to ensure that the bonding position is not biased.

Step 2: Make the inner frame

After the glue on the outer frame dries, measure the size of the inner frame, then cut out two 4mm diameter bamboo sticks of corresponding length according to the size, and glue them at a distance of 42mm from the outer frame. Finally, complete the shorter part. Wait for the glue to dry completely!

Note: The length of the small squares in the picture above is 42mm!

Today’s content ends here, you need to wait for the glue to dry!

【DAY-03||2017-07-17】Build the first floor of columns

1. Build pillars

Step 1: Prepare materials

First cut out a total of 16 bamboo sticks with a length of 156mm and a diameter of 4mm, then slightly sharpen the head, and use a drill to drill holes at the corresponding bonding positions on the frame made earlier. Do not punch through, just There needs to be a slight trace to ensure that the bamboo stick can be fixed

Step 2: Foot positioning

Find a flat platform, which can be a wooden board or a table top, then draw a square with a length of 250mm and glue the feet on it

Note: The feet should be bonded to the outside of the square

Step 3: Post positioning and bonding

First glue on the four outer columns, and then use the materials on hand to temporarily make a few plumb bob positioning to ensure that the position of the frame is in the center when the columns are bonded

Note: The iron block in the picture above is to fix the position of the frame, and the small thumbtacks hanging from the two feet are for positioning

Step 4: Glue all columns

After the upper frame is slightly fixed, the remaining columns can be glued on

You need to wait for the glue to dry, so get here today!

[DAY-04||2017-07-18] Thickening the first layer of frame and laying the floor

1. Thicken the first layer of frame

Step 1: Cutting materials

First cut out 4*5 square bamboo sticks with a length of 230mm and a side length of 4mm (proportionally, it needs to be thickened by about 5 layers). It is best to choose bamboo sticks that have no bamboo knots and are relatively straight. The length can be adjusted according to your actual situation

Step 2: Layer-by-layer bonding

Add the cut bamboo sticks to the frame layer by layer. After each layer is adhered, use rubber bands or clips to secure it to ensure a strong bond. After one layer is completed, the next layer is continued until complete

Note: It will take a long time to wait for each layer of bonding to be completed. At this time, you can start making the rice-shaped frame on the column. If you want to start, please go to the subsequent rice-shaped frame production content. !

2. Laying the floor

When the thickened frame glue is dry, you can start laying the floor!

Step 1: Cut the material

According to the length of the floor frame, cut out 10*4 bamboo sticks with a diameter of 4mm. The length needs to be measured according to your own situation. The number of bamboo sticks is also related to the size of the frame you make, soNeed to make adjustments according to actual conditions

Step 2: Laying the floor

The poster here used two methods to lay the floor, explain them respectively

Method 1

First glue the bamboo sticks together to form a whole piece, wait until the glue is firmly bonded, and then glue it to the frame. This is the method that the original poster used at the beginning. This method is easier to operate, but it affects the size of the frame. High accuracy requirements

Method 2

Fix a bamboo stick at the bottom of the frame as a bracket, and then glue the bamboo sticks to the frame one by one. This method is a little more troublesome and much slower to operate, but the effect is the best

Note: The rubber band in the picture is used to fix the bracket under the frame, and the bracket holds up the bamboo sticks bonded to the frame

The next step is to wait for the floor to be fixed, and that’s it for today!

[DAY-05||2017-07-19] Making the inner frame of the column (1) and the outer edge of the frame

If the previous content requires skills, todays content requires only one thing, and that is patience. The more delicate and beautiful the rice frame is made, the more it tests ones patience. Be patient, come down and start!

1. Make the rice grid inside the column

Step 1: Make the beam

Make marks (3 points) on the uprights from bottom to top at intervals of about 42mm, and then cut out bamboo pieces about 1mm thick and 2--3mm wide according to the marked positions, with a 45° bevel. Once bonded, all four sides are processed in sequence

Step 2: Use the word rice

Use a bamboo stick of the above size in the middle of each beam, cut it to the actual length, and glue them one by one until the first column is completed

2. Outsourcing edges

Add a layer of edging outside the fifth layer of the thickened frame, slightly higher than the fifth layer of the frame. As shown in the picture

Note: This picture was taken in the later process, so some content has not been explained yet. Here you only need to pay attention to the outer border!

Note: If you still have the patience after completing the first column, you can continue to complete the remaining columns

There is not much content to do today, but the author has already done it and has no patience to do the second one, so here we go!

[DAY-06||2017-07-20] Rice frame (2) and layout of the first-floor LED light system (1)

1. Arrange LED lighting system

Step 1: Circuit planning

Feasibility analysis:

The USB port of the power bank provides a DC output of 4.5-5V, and the current can reach 1-2A; while a blue LED light has a rated voltage of about 3V, a current of about 20mA, and a yellow LThe rated voltage of the ED lamp is about 2V and the current is about 20mA. In this way, one blue lamp and one yellow lamp can be connected in series, and then connected in parallel with other groups. The output current of the power bank can accommodate as many as 50 to 100 groups, so It is completely feasible, and multiple groups of parallel connections can effectively reduce the number of LEDs affected by faults

Circuit design

Based on the previous analysis and considering the actual number of light sources that need to be arranged, draw a schematic diagram of the circuit diagram as follows

Note: In the above picture, the blue circle represents the blue LED, the yellow circle represents the yellow LED, the thick red line connecting the blue and yellow represents the series connection, the thin red line represents the positive line, and the thin black line represents the negative line. The picture is just for illustration, just remember that the connection logic is one yellow and one blue connected in series and then connected in parallel in groups!

Step 2: Wiring design

In order to make the wiring look simple and uncluttered, it is necessary to leave interfaces for the second and third layers of wiring. Therefore, when wiring, arrange a circle of negative wires directly in the yellow light area, and outside the blue light (i.e., the thickened part of the frame) Arrange a circle of positive wires, and then glue the internal yellow and blue lights to their respective positions

?

Step 3: Soldering the circuit

After welding the wires, use a lighter or wire strippers to pull out the interface at each LED, and then solder the yellow and blue lights respectively. The result after welding is as follows:

Note: When welding, remember not to put the welder too close to the LED light, and the welding time cannot be too long, otherwise the LED light will be burned out!

2. Make the rice frame of the second column

The production of the rice-shaped grid is the same as before, just refer to the previous step. The reason why the author made the rice-shaped grid with four columns separately is because it is easy to get tired of doing repetitive things! Today Be sure to complete the second column with a square meter!

Today’s content ends here!

[DAY-07||2017-07-21] LED light system modification

In fact, the solution adopted by the original poster at the beginning of the design was not the one described yesterday, but a method of connecting multiple yellow lights and multiple blue lights separately in series and then in parallel. However, after welding, it was found that the connection could not be connected. It was normal, so I changed the plan, rewired and welded it once, which cost the author an extra night.

PS: The host works during the day and does all the work at night!

[DAY-08||2017-07-22] Rice grid (3) and LED light system (2)

1. LED light system USB interface design

We have completed the circuit and welding of the first layer of LED light system. Now we need to lead out the four interfaces of the two positive and negative wires, and leave two of them (one positive wire and one negative wire) As the second layer interface, the other two are used as power input ports.

Step 1: Prepare and modify the USB interface

The USB interface can be purchased online or removed from an existing device. Generally speaking, it will be available in old mobile phones or other smart devices. The poster removed it from an Arduino chip that was used out before.

Note: Be careful not to damage the USB pins during disassembly!

Step 2: Solder the USB port

The removed USB has 6 pins, two of which are used to connect power, while the rest are used to transmit data, so you need to find these two power interfaces. Use a multimeter to find the positive and negative pins of the USB interface. If you don’t have a multimeter, don’t worry. Below I will introduce how to find the pins without a multimeter

How to use a multimeter to find the positive and negative pins

First, use a power bank to connect the USB, and then use a multimeter to measure the terminal voltage of each pin. Find the two pins that can stabilize the voltage at about 5V, which are the positive and negative poles.

How to find the correct positive and negative pins without a multimeter?

First, use a power bank to power the USB port, then take a normal LED light and connect the positive and negative poles of the LED light to each USB port. When the LED lights up, you have found the correct pin. , write down the positions of these two pins, Note: distinguish the positive and negative poles!

After finding the positive and negative pins of USB through the above method, use electric welding to weld the two positive and negative wires left before to the positive and negative pins. Be careful not to reverse the positive and negative connections!

Step 3: Fixed USB interface

Open a small slot at a suitable location under the frame, fix the USB interface to the slot and fix it with hot melt glue (you can also use other glue, but be carefulnot to let the glue enter the inside of the USB interface. Otherwise, the circuit may be insulated and cannot be connected. After the installation is completed, test whether it is normal

Note: The position of the USB interface here seems unsightly, but don’t worry, a fixing rod will be added here later, which will cover most of the position! . In addition, in the second picture, you may find it strange that since the USB is located under the frame, how can you not see the pillars? This is because when the original poster came here, he found that the pillars were not very well made, so he removed the pillars and wanted to redo them. one time! This will be discussed later. I hope everyone will get it right in one step and not follow in the footsteps of the original poster. It’s really hard!

2. Rice grid production

Next, follow the previous method to complete the rice-shaped grid of the third column. The author will not go into details here!

[DAY-09||2017-07-23] Rice grid (4) and laying the first floor

1. Lay the first floor

Step 1: Fill inside the frame

First, fill the internal size of the frame to about 100mm*100mm. The author here has about three layers of 4mm diameter bamboo sticks embedded in it

Step 2: Prepare bamboo slices

Make the corresponding bamboo shape according to the following drawings

?

Step 3: Bonding the bamboo pieces

Adhere the bamboo pieces bonded above to the corresponding positions of the inner frame, as shown in the picture:

Step 4: Set up pillars

Build four pillars on the four corners of the 100mm frame, and then glue a square circle on them to serve as a bracket. The height of the bracket should be exactly the same as the height of the thickened fourth layer on the outside. It is appropriate

Step 5: Laying the floor

Refer to the picture below to cut out 4mm diameter bamboo sticks of corresponding length and lay them on, and use glue to bond them. Note that the tips of the bamboo sticks here can be slightly higher than the edge layer, because they need to be polished and smoothed next. After laying, wait for the glue to set.

2. Complete the rice grid

While waiting for the floor to be firmly bonded, you can start completing the rice grid of the fourth column!

The results after the completion of the four columns are as follows:

That’s it for today!

[DAY-10||2017-07-24] Making the first staircase

1. Make stairs

Step 1: Plan the length of the stairs and the number of steps

There is actually no specific requirement for the length of stairs, it just depends on personal preference. The poster here chose to add three beams on each side based on the previously laid floor, so that the length of the stairs is about 70--80mm, and the width is 20mm; the number of steps is determined according to your slope, step distance, etc.< /p>

Step 2: Prepare materials, cut and bond

After considering the specific parameters of the stairs, we started to make them. First, we glued the two baffles on both sides of the stairs according to our own size. Then we cut out the steps of corresponding length and glued them on. After the glue was fixed, we put the stairs in. Fix it with glue inside the frame

Step 3: Fill in the gaps and complete the details

Use bamboo pieces to fill in the empty part completely, and use glue to bond it firmly. The completion is as follows

Note: Today’s content is very small, but it is really inconvenient to only build stairs, so please be patient

[DAY-11||2017-07-25] Polish the floor

1. Polish the floor

Use a small plane to polish the floor flat. During the polishing process, be careful not to use too much force, otherwise the feet will be deformed or even damaged. The original poster used too much force and caused serious deformation of the feet, so he removed the feet and re-glued them. once.

Adjust the depth of the blade of the small plane and slowly polish the floor. This process is more difficult, so everyone needs to be patient. The polishing standard should be that the floor is basically flush with the outer edge

Today’s content is a bit difficult, so you need to be patient and finish it slowly!

[DAY-12||2017-07-26] Making the inner corridor on the first floor

1. Make a corridor top bracket

Step 1: Prepare the bracket

Refer to the drawing of the bottom bracket to make a correspondingly shaped bracket

Step 2: Bonding the bracket

Adhere the prepared bracket to the corresponding position of the inner frame of the floor and wait for the glue to stick firmly.

2. Make corridor guardrails

Step 1: Build guardrail columns

Cut out corresponding lengths of bamboo sticks or bamboo pieces with a diameter of 2.5mm as shown in the picture and glue them on according to the positions shown in the picture. Because the space is relatively small, it is inconvenient to glue and requires some patience!

?

Step 2: Perfect the details

After setting up the columns, glue the horizontal rails and the small column in the middle

After completion, you can turn on the LED light to see the effect. It is found that there is light leakage in the middle of the floor and needs to be repaired

3. Repair floor gaps

Use wood glue to apply an even layer on the floor. Apply more to areas with larger gaps and wait until the wood glue dries to see the effect

The effect of wood glue after drying:

Note: If the wood glue is still not effective after it dries, you can apply it a few more times!

That’s it for today!

【DAY-13||2017-07-27】Add hood and adhesive feet

1. Add a hood

Observing the demonstration effect of the front lighting, we found that although the gap has been filled, the light will still pass through, so we considered adding a shading board here

Add sunshades

Use a cardboard shell to cut out the corresponding size, and then use 502 to glue it to the LED light as a light shield

2. Bonding feet

After the lens hood is added, the first layer of the platform is basically ready. Next, glue on the previously removed feet

Step 1: Use the original positioning method when bonding, wait for the glue to dry before continuing the operation

Step 2: Add fixed column

Use beam positioning at 16 foot bracket positions to increase its stability

That’s it for today!

[DAY-14||2017-07-28] Making the bottom arch (1)

1. Make the bottom arch (1)

When making the arc door at the bottom, pay attention to bonding the feet to the table first, otherwise the bent bamboo pieces will spread the feet!

Complete the production of two arches today!

Step 1: Build an arc

Cut the bamboo pieces of corresponding length according to your actual size, and then use 502 to glue them on. Note that the arc here includes two layers, inside and outside, and there are two layers inside and outside

Step 2: Make the small grid inside the arch (1)

[DAY-15||2017-07-29] Making an Arch (2)

1. Perfect the arch

Finish the small grid on the unfinished arch in front, pay attention to the inner and outer layers! This is more time-consuming, so be patient!

[DAY-16||2017-07-30] Making the second layer of framework

1. Make the second layer of framework

Step 1: Make the frame

First, cut out 4 square bamboo sticks with a length of 118mm and a side length of 4mm, and glue them together; then, according to the width of the surrounding small squares of 27mm, cut out bamboo sticks of corresponding length to complete the interior

Step 2: Drilling

After the frame is firmly glued, use a drill to drill a total of 16 holes at the intersections of the bamboo sticks. Then use a drill to drill 16 holes on the first floor. The hole position is 10mm from the edge and the width is 30mm

?

Step 3: Build a framework

Cut out 16 brackets with a length of 170mm, sharpen both ends, and then build them. Use the plumb bob method mentioned earlier to position them to ensure that the frame is in the correct position.

Note: Please note that when punching holes, you need to punch one more hole to connect the wires on the first layer. Please look carefully at the positions of the two wires in the picture!

The function of the line in the above picture is to position the frame!

Note: The bracket takes a long time to fix, it is best to wait overnight!

That’s it for today!

[DAY-17||2017-07-31] Make the second layer of rice grid (1) and the second layer of thickened frame

1. Thickened frame

Step 1: Thicken the frame

First make 4 square frames according to the size of the upper frame on the second layer, glue them together, and then wrap two layers around the fourth layer, as shown below

Step 2: Cutting and binding

First cut off the four corners of the hemming

?

Use bamboo slices for wrapping after cutting

Step 3: Build floor supports

After the thickening work is completed, bond it to the frame, and then make four columns according to the idea of ????one layer, and put two beams on the columns to support the floor. The height of the beams here is the same as the height of the frame. It is appropriate for the four layers to be flush with each other

Here we go today!

[DAY-18||2017-07-01] Making the second layer of rice grid (1)

1. Make a rice grid (1)

Step 1: Install beams

Divide it into four parts from bottom to top according to the spacing of 42mm, and then use bamboo slices to build the beams

Step 2: Make a rice grid

Follow the production method of the first layer and complete the beams of two of the columns with a square pattern

【DAY-19||2017-08-02】Production of rice grid (2) and second layer circuit design

1. Design circuit

Step 1: Circuit design

With the foundation of the first floor, the second floor is much more convenient. The authors approach is to place 8 blue lights on the eight corners. What needs to be noted here is that the circuit still follows the idea of ????one blue and one yellow in series. , and there are only blue lights here, so you need to leave a line for all the lights and wait for them to be connected in series with the yellow lights on the upper layer

After the installation is complete, be sure to test whether it is normal

Step 2: Laying the floor

Next, lay the floor

Use a small plane to smooth the surface, then fill the gaps with white latex

?

2. Perfect the rice grid

Next, follow the previous method to complete the rice-shaped grid of the second layer of the oracle. This part is relatively simple, but it also tests your patience!

That’s it for today!

[DAY-20||2017-08-03] Perfect the rice grid (1)

[DAY-21||2017-08-04] Perfect the rice grid (2)

Although the previous poster said that the rice-shaped grid was completed, in fact during the production process, due to detail problems and his own dissatisfaction, he still more or less disassembled and redone parts, so he spent an extra two nights, which can be regarded as Relax! Also tinker with some of the details you made earlier.

[DAY-22||2017-08-05] Make the first small house on the second floor and arrange the circuit

1. Build the frame of the house

The height of the house is about 10mm, and the length and width are 60mm

Step 1: Make the frame

First cut out a total of 8 bamboo pieces of 5mm width and 60mm, glue each two pieces together, and then make doors and windows on two of them

Step 2: Glue the house

Add the frame of the house you just made, and place it in the middle

2. Lay out the circuit

Step 1: Lead

Drill holes in the four corners of the house and lead up the negative wires of the eight blue lights below and the positive and negative wires of the bus

Step 2: Welding yellow light

Weld four yellow lights at the four corners of the house, connect them in series with the four blue lights just now, and then connect them to the bus in parallel. The other four leads of the blue light remain on

Test the effect after welding

Note: The yellow light here is connected in series with the four previous blue lights, so when testing, you must also check whether the blue lights are normal!

That’s it for today!

[DAY-23||2017-08-06] Making a second small house and wiring

Step 1: Make the floor

Make a square frame with a width of 110mm. Pay attention to the location of the stairs. The width of the stairs is about 15mm. The corners of the two stairs are half of the floor.Width

Step 2: Hemming and smoothing

Next, cut off the four corners of the floor and then edge them, and also edge the stairs

Use sandpaper and a small plane to smooth the floor

?

Step 3: Make a 2-story small house

Cut a total of 12 5mm wide bamboo pieces according to the dimensions of 45mm wide and 60mm long, then make doors and windows and glue them to the floor

Step 4: Wiring

Still like the small house in front, drill four holes in the four pin positions and lead up the four negative blue light wires and the bus left in front

Weld yellow LEDs at the four corners of the house. Here, the four blue LED light lines drawn from the front are connected in series with the yellow LED lights and then in parallel with the bus. Up to now, the previous 8 blue LED lines have been used Finished, only two buses remain

【DAY-24||2017-08-07】Making roof and ceiling light wiring and making stairs

Step 1: Make the octagonal roof

Cut out enough bamboo pieces with a length of 75mm and a width of 5mm, then glue a square cover according to the size of 75mm, open a 20mm square hole in the center, then cut 20mm on each side, and then wrap the edges

Use sandpaper to smooth

Step 2: Roof light arrangement

A yellow light is arranged on the two sides of the octagonal roof close to the stairs to serve as lighting for the stairs. Note that the yellow lights here are still connected in series with one blue and one yellow, so the two negative wires need to be connected. Save it for later use

Step 3: Make the stairs

First use 5mm wide bamboo pieces to build the steps, and then cut them according to the corresponding width

Insert the stairs. This requires some skills and patience. It will take several times to install them beautifully

Here we go today!

【DAY-25||2017-08-08】Reset roof lights and create grids

1. Reset the roof lights

Although I talked about welding the roof lights yesterday, the poster later discovered that there might be a short circuit during the wiring, so one of the lights was burned out, so the poster had to weld it again. The location was extremely inconvenient, so the welding cost a lot. Time

2. Make a bamboo stick grid

Taking advantage of the free time after the welding was completed, the author made another grid that needs to be used on the first floor. This grid is mainly used in the internal position below the frame on the first floor

Step 1: Prepare bamboo sticks

First, you need to split the bamboo sticks or bamboo slices into thin rods of about 1mm

Step 2: Bonding

Join the split bamboo sticks at an inclination of 45 degrees. When gluing, be careful to ensure that every position is bonded, otherwise they will break when cutting during subsequent use

Here we go today!

【DAY-26||2017-08-09】Build the third layer of columns

Step 1: Make the frame

First, cut out 4 square bamboo sticks with a side length of 4mm according to the width of 40mm, and connect them at a 45-degree angle. Then add the cross beam in the middle and wait until they are firmly bonded.

Step 2: Create a restriction box

Cut out bamboo pieces with a length of 50mm and a frame of 5mm, and then glue them according to the dimensions measured from the outside to a width of 50mm, add a middle beam, and then make four small openings in the four corners

Step 4: Set up pillars

Cut out 4 pieces of bamboo with a length of 370mm and a diameter of 4mm, and sharpen both ends. Use a drill to drill 9 holes (without drilling) on ??the two frames you just made, and also drill holes 10mm from the edge of the floor. Carve notches at the height of 130mm on the pillars.

Then bond and use a plumb bob to position to ensure the center position

Adhere the fixed frame to the notched position and secure it with rubber bands

Still using the plumb bob for positioning

Wait for the glue to stick!

Here we go today!

[DAY-27||2017-08-10] Make fine mesh and improve the second layer of details (1)

Today, the poster wanted to make the glue fixed more firmly, so he did not proceed further, but turned to improving the previous details

1. Make fine mesh

Follow the previous rough mesh method, prepare the bamboo fibers, and then use 502 glue to bond them. However, the bamboo sticks here need to be thinner and denser. The mesh made here is mainly used for the details of the second layer

2. Improve the second level of details (1)

In the remaining time, the author improved some details on the second floor

?

Here we go today!

【DAY-28||2017-08-11】Put up the middle column and solder the circuit

Step 1: Set up the middle column

Punch four holes in the octagonal cover, punch holes in the floor below, and then set up columns, as shown in the picture:

Step 2: Solder the primary circuit

Weld a blue light on each of the four corners of the fixed angle. The circuit logic is the same as before, leaving the negative terminal open

Although it is not difficult to build the column, it is becoming more and more difficult to solder the circuit because the location is getting narrower. It takes a lot of time. When welding, be careful not to put the welder too close to the LED, otherwise it will easily burn out. LED. After welding, use hot melt glue to fix it

Today’s content ends here!

【DAY-29||2017-08-12】Making sky loft and welding circuit

Step 1: Build the building

Add the building body from the limit frame to the top 1/3, and the height of the building body should be about 15mm

Step 2: Solder the circuit

Weld four blue LEDs on the four inner corners of the building. The circuit logic is still one blue and one yellow connected in series and then in parallel, so the four negative wires are left out

Step 3: Build a beam

Rotate 45 degrees to the top of the building and glue the transverse beams as supports

Step 4: Make the roof

Measure the dimensions of the roof and then glue the corresponding shape

Next, glue the roof on and wrap the edges

?

That’s it for today!

[DAY-30||2017-08-13] Making the top first-level tower

1. Make the tower body

Step 1: Bonding the top of the tower

First, use 40mm long and 5mm wide bamboo sheets to bond, then add a thick layer on the outside and wrap the edges

Step 2: Bonding the pillars

Cut out 4 bamboo sticks with a length of 50mm and a diameter of 4mm and glue them to the top

Step 3: Glue and thread

Adhere what you just made to the top of the tower and wait for the glue to dry

Punch a few threading holes in the middle and thread the thread through the middle

2. Make side details

Step 1: Inner Grid

First fill in the internal details with the fine mesh made previously, and then glue a few columns on the sides

?

Step 2: Build the outer perimeter of the tower

Cut 12 bamboo sticks with a height of 15mm and a diameter of 2mm and glue them to the pillars at the foot points as supports, and then glue the beams

3. Soldering circuit

Weld 4 yellow LEDs here, pay attention to connect them in series with the blue LED light lines left before and then connect them to the bus

That’s it for today!

[DAY-31||2017-08-14] Making the first floor of a small house

Step 1: Frame the house

Make the house frame according to the dimensions of length: 38mm and height: 30mm

Step 2: Perfect the details of the house

Build details such as doors and windows

Step 3: Soldering LED

Solder four yellow LEDs at the top of the four corners, the circuit logic is the same as before

Step 4: Make roof decoration

Make a total of 8 small decorations according to the size of 20mm in diameter, and install four of them on the four corners of the roof

Now let’s test the circuit effect

In the picture above, we found that there are many places where the light is too strong. We will do some shading in the future, but don’t worry about it for now

Here we go today!

[DAY-32||2017-08-15] Making a second-story small house and improving the details

Step 1: Make the house frame

According to the dimensions of 38mm length, width and 20mm heightCreate a frame

Step 2: Complete details and glue

Complete and glue the doors and windows of the house to the top of the tower, and install the four decorations made previously

Step 3: Solder the four-corner LEDs

Pull out wires from the four corners of the decorative position and solder the LED

Step 4: Perfect the decoration

After welding the LED and testing it normally, use a 2.5mm diameter bamboo stick to encapsulate the LED position

Here we go today!

[DAY-33||2017-08-16] Making the top of the tower

Step 1: Make the thimble

First cut out a bamboo stick with a diameter of 4mm and a length greater than 110mm, then cut out a number of bamboo sticks with a diameter of 2.5mm and a length of 60mm for wrapping

Note: The size of the original poster here is: the lower part is 60mm long, and I plan to leave 50mm on the upper part, but there is still a longer margin here, and I plan to cut it shorter as needed in the future!

Step 2: Make the ejector pin fixing device

Make the fixture according to the length, width and height of 15mm and 20mm

Step 3: Fix the thimble

Use hot melt glue to stick the ejector pin to the fixed position

Step 4: Making arcs

Use bamboo pieces to build an arc arch with a height of about 30mm

Step 5: Soldering LED

Solder four blue LEDs at the positions shown below, and connect them in series with the four yellow LEDs at the decorative positions, and then beautify the details

As of today, all the places where LEDs need to be installed have been completed. Now everyone should test whether there is any problem with their LEDs. What needs to be emphasized here is that all LEDs use one yellow and one Blue is connected in series and then in parallel to the bus. The original poster did not originally intend to add the four blue LEDs at the top, but found that when two yellow LEDs are connected in series, the LEDs heat up more seriously, and when three are connected in series, the power banks power supply voltage is insufficient, causing it to not light up at all, so in order The circuit is stable, and the author specially added four blue LEDs on the top to connect in series with the four yellow lights!

[DAY-34||2017-08-17] Improve details (1)

1. Production pane

Make a grid

Use chopped thin bamboo strips to glue into the grid, then cut and glue according to size

2. Build cross beams

Complete the three-story beam according to the drawing

Here is an overview picture:

[DAY-35||2017-08-18] Improve details (2)

1. Make an inner guardrail

Step 1: Prepare materials

Adhere the material according to the picture, height 20mm

Step 2: Bonding

Cut out the materials and glue them

2. Make a first-floor stair guardrail

The steps are the same as above, the effect is as follows

3. Make the second layer of guardrails

Second floor upper guardrail

Second layer lower guardrail

4. Make the first layer of peripheral guardrails

Step 1: The height is consistent with the middle of the internal meter grid, and the other methods are the same as above

Step 2: Laying the boards

The poster found that the bamboo pieces he bought before were not enough, so he went to buy some green bamboos

Split the bamboo above and cut it into bamboo slices and then lay the boards

5. Make the third layer of guardrails

The method is the same as above, and the effect is as follows

[DAY-36||2017-08-19] Improve the details (3)--making the battery box and connecting switch

1. Make a battery box

Although using a power bank for power seems a bit cool, it often brings inconvenience, so today the author plans to add a battery power supply solution to the tower, because the voltage needs to be about 5V, so use 3 No. 5 batteries are connected in series. The original poster bought a three-cell battery box online

3-cell battery box

However, I found out that it was too big to fit in. I had no choice but to make one myself.

Step 1: Make a battery box

Cut out the two terminals inside the battery box

Step 2: Make a battery box

Adhesive bamboo sticks

Glue the box and solder the terminals

Make a box lid

Adhere to the bottom of the first floor of the tower and connect the wires to the bus, paying attention to the positive and negative poles

?

Step 3: Welding switch

After the battery box is completed, open an opening near the USB interface and then solder the switch on it

Note: The switch used by the poster is called a self-locking switch, and I bought it from the Tmall store!

Now, this tower can be powered by either battery or USB. Of course, it can also be powered on and off by using the switch normally.

Let’s test the effect

That’s it for today!

[DAY-37||2017-08-20] Improve the details (4): Make the third layer xx

[DAY-38||2017-08-21] Improve the details (5): Make the third layer xx

There is nothing to say about this, it is just a repeated process. The author spent two nights here

[DAY-39||2017-08-22] Improve details (6): Modify the head lantern shell

After completing the previous content, the original poster felt that the lantern on the head was too big and particularly ugly, as follows

So the original poster planned to tear it down and redo it.

When I dismantled it, I found that the 502 was really firmly glued. Please be careful when dismantling it. Don’t damage other structures and worry about hurting your hands. This is where the poster accidentally used the pen knife. Scratch your handI had three wounds, and I was scratched when I was almost done. I was really drunk!!!

After dismantling the previous structure, reduce the 270° missing circles in the upper and lower parts, and then use bamboo sticks to bond and fix them, as shown below:

Doesn’t it look much better now~~

Today’s project really tested both my patience and my skills. It took me most of the night to finish it, and I even hurt my hand. I’m not happy, so go to bed!

[DAY-40||2017-08-23] Make a one-story chair

Today’s content is relatively easy, just make the first layer of chairs, just follow it as a reference

Make the chair first

Make the arc again

Finally glue it on

Up to now, we have completed all the content that needs to be produced. As for some areas that need to be improved or modified, we will consider it later. Take a few pictures to see the final effect:

[Write at the end] Conclusion

After more than 40 nights of work, this work is finally completed! I always feel that DIY is a kind of fun, but there are also boring moments in the process, such as when making the rice grids and grids of this tower. You have to keep repeating the same content. In addition, using tools will inevitably hurt your hands. This time the poster accidentally cut his hand when he was about to finish it. It is also common to get burned by hot melt glue and have his hands full of 502. However, it is fun to do it and it is worth it. !

This Eiffel Tower tutorial can be regarded as one of the more detailed DIY tutorials I have written. It is also based on the hope that people who want to do it can understand it.Let me write. If it is helpful to everyone, don’t forget to give the author a like!

The damn thing is, in the past two months, I have been working during the day and doing towering at night. I haven’t exercised for two months, and my abdominal muscles have become one~~ I’m so happy!

Finally, the pagoda is ready and the time is just right. So the question is, how to give it to my favorite young lady in a reasonable and pleasant way? !

?

![[Paper Model] Halloween paper model Rilakkuma and his friends free drawing download](https://img.111diy.com/timthumb.php?src=/d/file/20220217/1neof3cdpgu.jpg&w=200&h=200&zc=1)