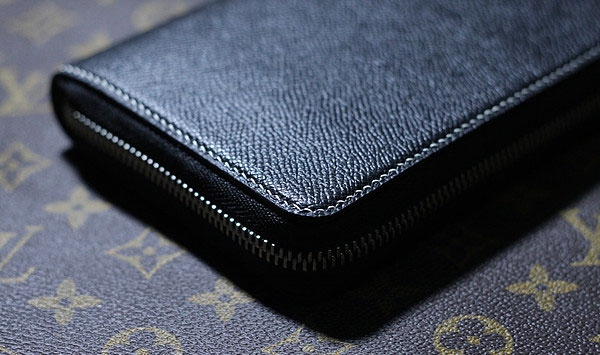

Author: Flato, WeChat: k9999w11 When posting original tutorials, you must have the habit of taking pictures when making. This time I just counted the pictures of the mens handbag. Although the pictures are not particularly complete and detailed, they are enough for original posts and can be used just right. Let’s share some of the production methods of chrome tanned leather (I dare not talk about the techniques). 1. Introduction of all-inclusive materials. Inner and outer skin: HAAS Epsom palmprint leather. Pad material: vegetable tanned leather. First layer. Back patch: thin nylon cloth. Glue: polyurethane glue. Wire material: Zhijian hand stitching (only one store in Ma Shou Fu family sells it. Search directly) Side oil: Finnis matte side oil (non-heat repair) Zipper: YKK Excella (card reference, not guaranteed to be authentic) 2. Skin treatment

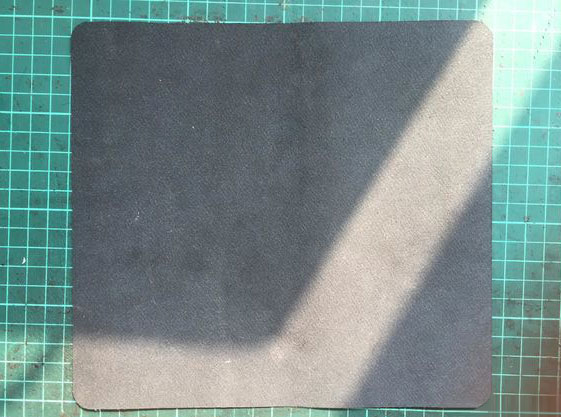

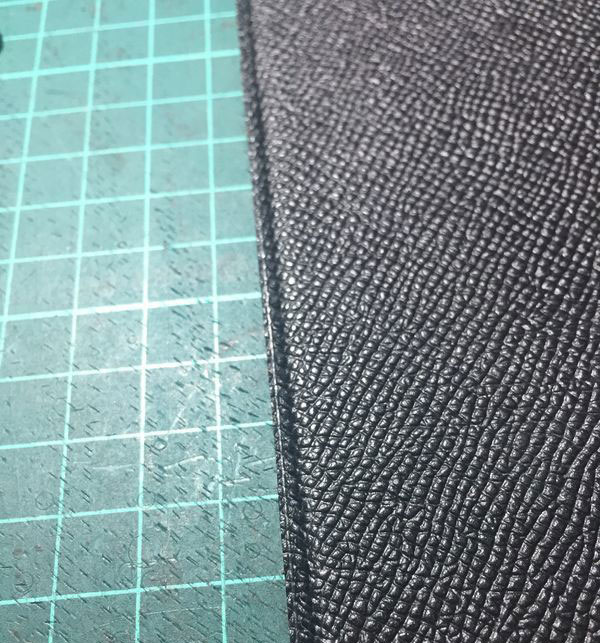

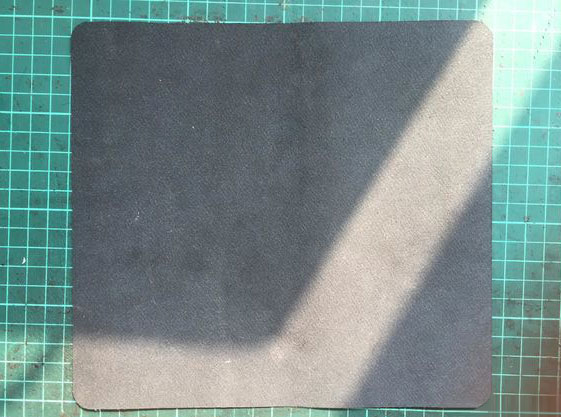

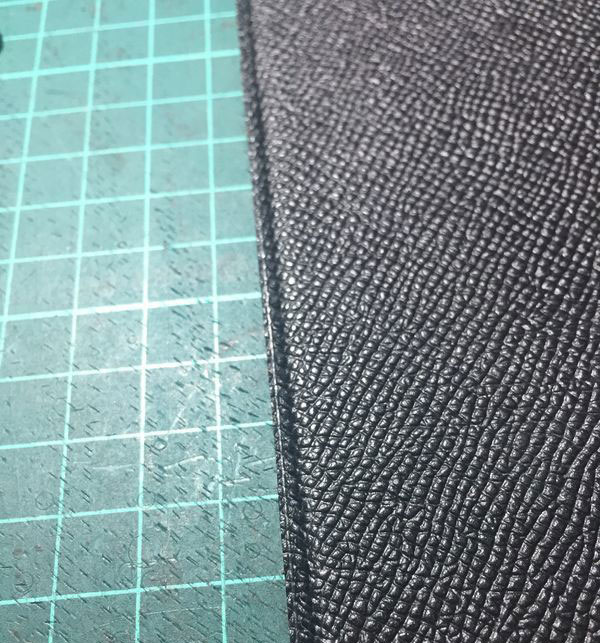

Take a piece of 23*20cm epsom leather with a thickness of 0.8mm and chamfer the edges with a chamfer radius of 1cm.

Take a thickness of 1.2mm Vegetable tanned leather, size 22.3*19.3cm, used as a drum pad to stick to the inside of the epsom above, leaving a width of 3.5mm around it.

Turn it over and use plastic The tip of the shaped stick is used to create a drumming effect.

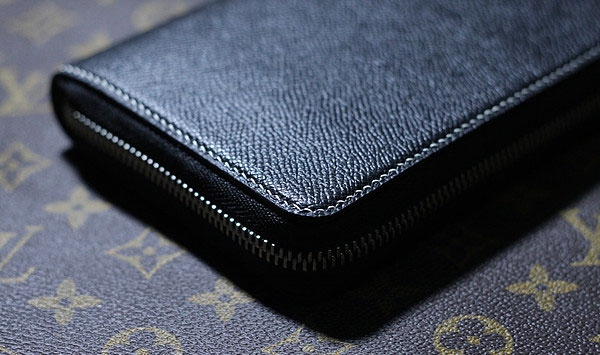

The edge ironing device irons out the edges. Use the 3mm method to cut the hole on the inside of the sideline.

Use a sponge to soak in water-based edge oil and apply it around the outer skin. There is no shortcut to edge oil. You need to be patient and apply it over and over again until you are satisfied. . Once the outer skin is processed, set it aside for later use. 3. Inner skin processing

The inner leather processing is relatively simple. Take a 22*20cm piece of leather, make a semicircular recess with a diameter of 1.5cm above and below the center line, then iron the edges and cut from the back. The above picture is not complete, and it will be shown in the following pictures. The effect is good, I forgot to take a picture and save it, I'm sorry everyone 4. Handling the change card slot

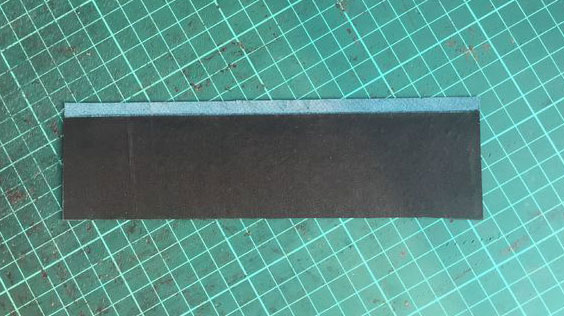

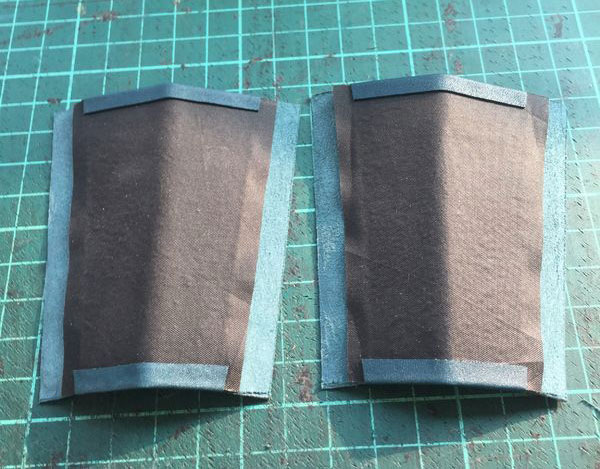

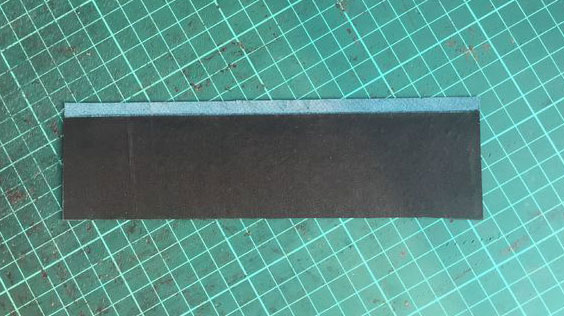

The card slot size is 19*5.5cm, and the upper 1cm width is thinned, as shown in the picture above, to facilitate the folding process below.

As shown in the picture, after aligning with the thinned edge, stick a A thin sheet of nylon cloth is used as lining to enhance the strength and durability of the leather.

The effect after folding the edges.

After the three card positions are completed, iron the edges.The edge is ironed and the edge width is 1.5mm.

< img src="http://img1.pixiaojiang.com/595b20f8dd4d35220.jpg_e600.jpg" alt="">

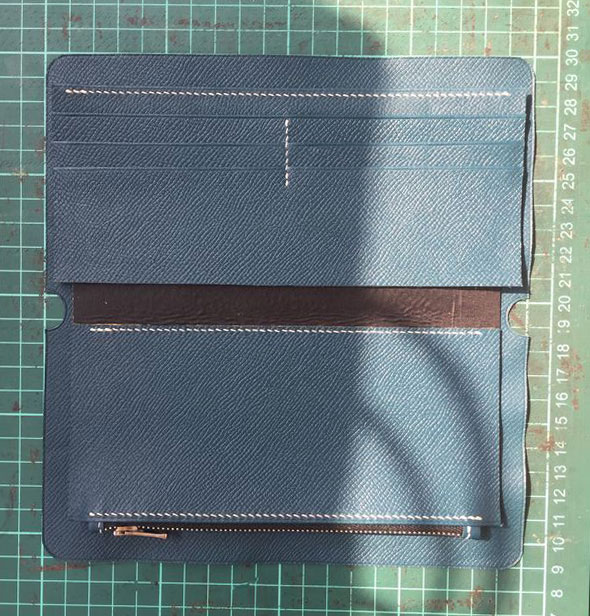

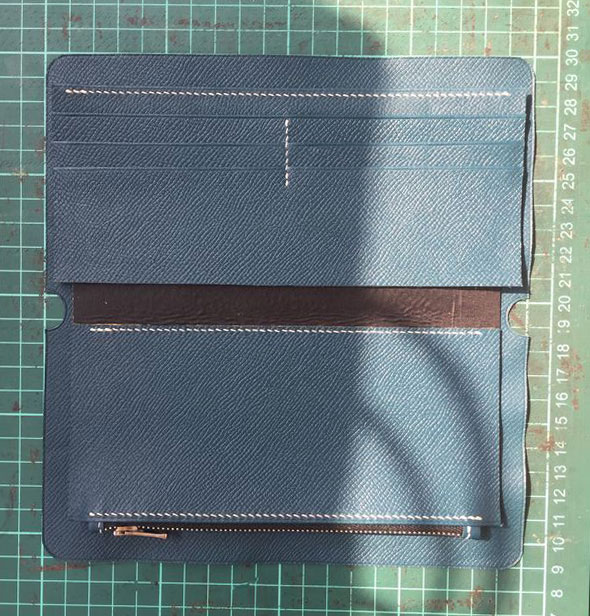

After finishing the process, make another note position (the one that is pressed at the bottom), and fold it in the same way. . Then cut the stitching line along the side line. (As can be seen in the picture, the back is not a wavy line. If the leather is thin, wavy lines on one side are enough)

Then combine the card position and the banknote position together, and cut the seam in the middle line. At this point, the change card slot is ready. 5. Coin bag and accordion pleat processing

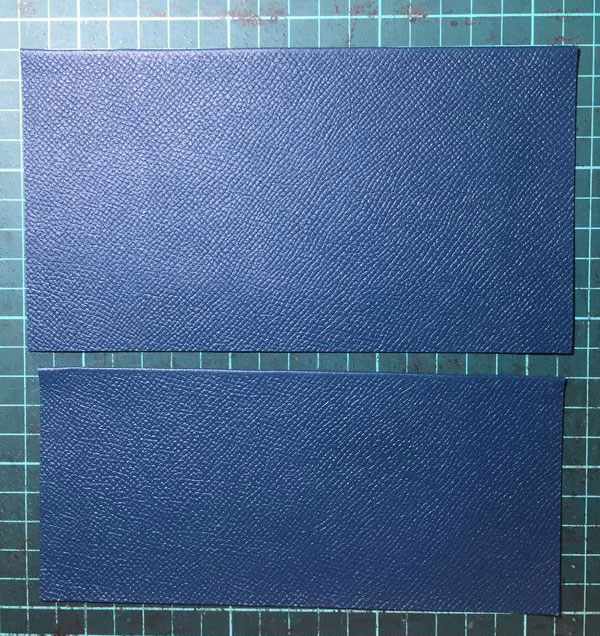

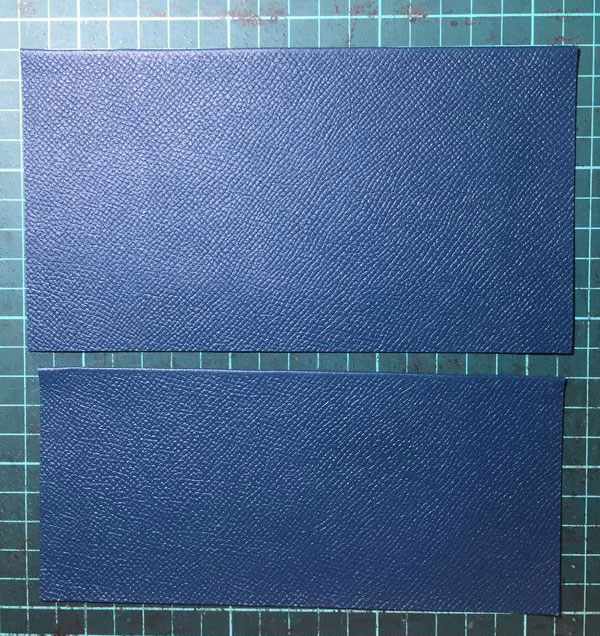

Take two pieces of leather for the coin bag, 11*18cm and 9*18cm, and fold them.

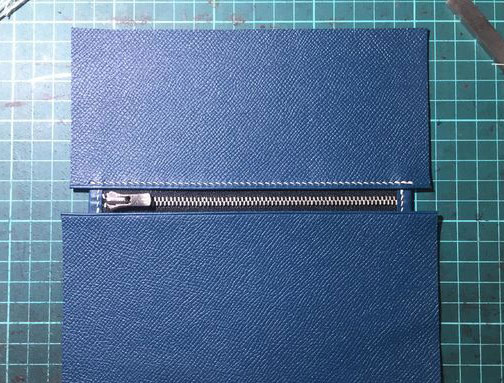

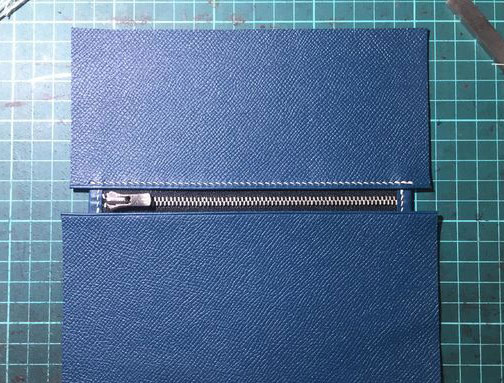

The two pieces of leather are combined with the zipper.

The lower end of the longer side of the leather overlaps the lower end of the coin card position just made, and is placed on the inner leather and sewed .

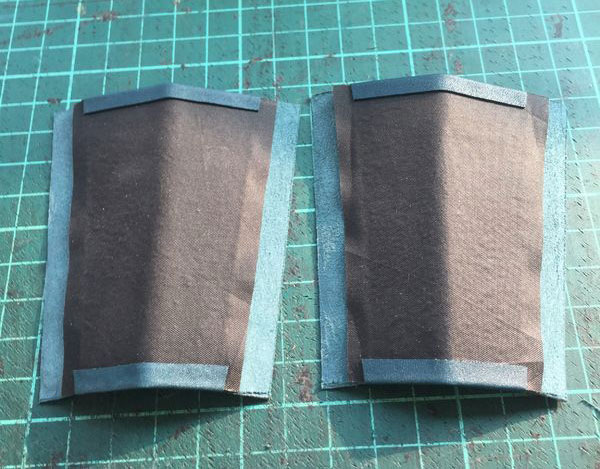

According to the width of personal needs, take two pieces of leather to make it Organ fold, all four circles are thinned, the width of both sides is 1.2cm, and the upper and lower folds are 1cm. The upper and lower parts are folded, and the left and right parts are left open for later use.

Connect the coin bag and the card slot with accordion pleats and sew. 6. Processing of ID slots

Take two pieces of leather and reserve them , the edges are thinned and folded.

Divide the short leather into three equal parts and sew on the equal parts.

Adhere the sewn ID bit to the other side of the inner skin, and remove the excess with a utility knife.

Iron out the edges, and now the interior of the handbag is completely finished. 7. Zipper processing

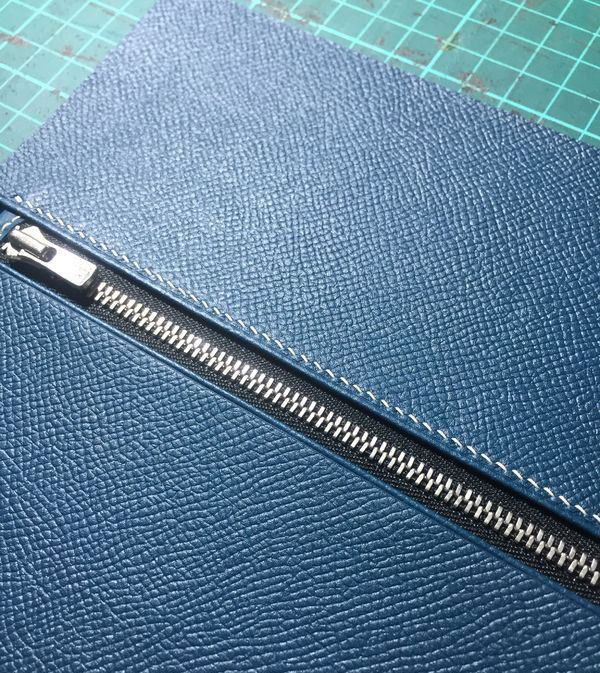

Take a 48cm zipper, remove the zipper teeth at both ends, and stick it to one edge of the inner leather of the handbag according to the calibration line on the zipper (the inner leather can be seen in the picture above Made notch).

Glue the zipper on the other side in the same way.

Glue the zipper on the other side in the same way.

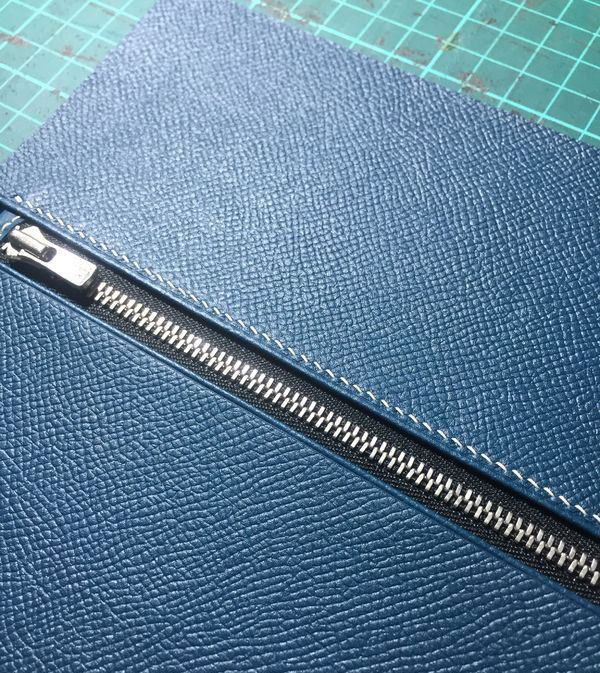

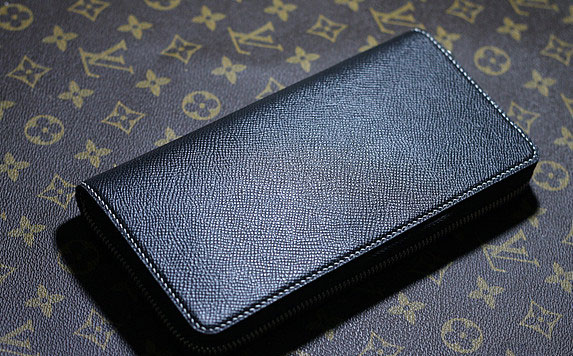

Glue the zippers on both sides and pull them up to see the effect. If the effect is satisfactory and no adjustment is needed, you can enter the final stage of outer skin stitching. (The zipper is the same as the side oil, there is no shortcut, you can only take your time) 8. Overall Suturing

There is no difficulty in overall suturing. As shown in the picture above, just align one side and glue the sutures together. Because the outer skin is larger than the inner skin, it is not difficult to sew this side and then glue the other side.

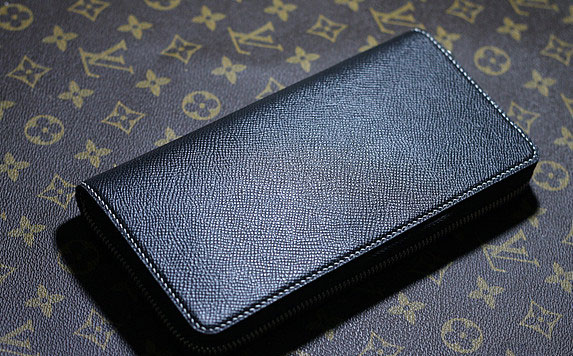

After both sides are sewn, the whole bag is finished.

The coin bag is open and closed.

The status of the banknote position.

The effect after the overall closure.

The effect of matte edge oil. 9. Treatment of zipper head

Take a leather strip with a width of 1cm and the length according to your preference, and make it into a zipper puller. Also create a bulging effect. Cut the seams on the iron side and oil the top. Very simple.

Use the 2.7 method to chop.

After done, place it on the zipper head and clamp it with pliers .At this point, the handbag is completed. 10. Completed drawing

< /p>

< /p>

This concludes the production of the chrome-tanned handbag. From the light in the picture, it is easy to see that the production of this handbag also takes several days. During the production process, it is indeed impossible to guarantee that the details can be photographed at all times. , please forgive me. If you don’t understand anything, please leave a message to communicate. See you next time.

Men’s Handbags

Glue the zipper on the other side in the same way.

Glue the zipper on the other side in the same way.

< /p>

< /p>