Tools used in this section of hardware installation

Why are installation hardware used in leather crafts? Various objects need to be installed, ranging from rivets that play an important role in the structure of leather crafts to decorative gems or other decorations

Accessories. Not surprisingly, the basic technique for installing hardware is the same: hammering. The difference is the installation tools, the base used, and the required strength. When to install hardware is either to connect the components together, install belt buckles, leather straps, or add purely decorative parts. Generally speaking, installation is the last step in completing the leather work. Although it is possible to stain the rivets and gas holes that have been installed, this will affect the hardware, appearance and staining effect. Just like repainting a car, the best results are usually achieved by completing all parts before assembly. Where to install hardware components

Whenever possible, it is best to install rivets on a flat metal surface like an anvil. Use a small 21-pound anvil on your work desk or chair, or even place an iron plate on top of the bricks (is it so difficult to get marble? I'm dizzy). Unless the anvil and mounting surface are attached, its a good idea to put a pad between the anvil (or brick) and the work surface to prevent vibrations that could cause the object to bounce and slide. How to install rivets

Whenever possible, it is best to install rivets on a flat metal surface like an anvil. Use a small 21-pound anvil on your work desk or chair, or even place an iron plate on top of the bricks (is it so difficult to get marble? I'm dizzy). Unless the anvil and mounting surface are attached, its a good idea to put a pad between the anvil (or brick) and the work surface to prevent vibrations that could cause the object to bounce and slide. How to install rivets

Using rivets to connect leather may be the simplest and fastest way, but it may not be the most appropriate, depending on what you want the appearance to be. Make sure the mounting holes are the right size and not too loose. Especially on thin leathers and suedes. If the mounting holes are too large, the rivets may slip off if pulled. Use the appropriate length of rivets you have on hand for the job. Not so important when using "quick" rivets, butYes, both solid and hollow rivets (tubular rivets) require a little margin to form the "base". Solid rivets If you need to join leather to a large piece of metal, and the installation location may have rotational movement, or need to bear weight, solid rivets are best. Any movement will cause wear on quick-release rivets where the leather and rivet come into contact. Insert the rivet from the mounting hole on the connector, expose the flat head from the front, and install the gasket on the striking surface. Use the deep hole part of the installation tool to press the gasket tightly onto the flat surface. Use a pair of pliers to cut it to a height of less than 2MM, but not flush with the gasket. Then use the concave part of the mounting part to hammer the protruding part flat, and rotate the mounting part during the hammering process. This will make the part above the gasket present a mushroom-shaped nail surface. This is the advantage of using a hammer several times rather than hitting it harder. In addition, this also requires rivet installation tools to be stronger and more durable than other tools.

Tubular rivets

This is a relatively solid rivet, usually in Used on automatic riveting machines. Suitable for connections with heavy loads. For example: attaching a heavy piece of leather to a belt, or installing a rivet to fasten a leather strip or buckle. Unless additional spacers are installed, it is not suitable for rotating leather goods. Because the overturned rivet teeth will eat away at the leather surface. It is ideal to use nail feet to protrude 2-3MM rivets from the leather. Push the nail feet through the connecting hole to expose the nail head from the leather surface. Place the installation tool firmly in the nail leg opening. Make sure the installation tool is perpendicular to the leather/anvil surface and hammer hard until the rivet splits and feeds firmly into the leather.

Quick-install rivets< p style="text-align: center;">

Quick-install rivets< p style="text-align: center;">

This kind of rivet may have the most complete surface treatment. The rivets with the largest sizes are divided into single cover and double cover. These qualities make them useful in leather art, from fastening trim pieces to fastening straps and buckles. Although a little weaker than tubular rivets, it can handle most leather armor production, especially when several are used in succession. For example: use three leather strips arranged in a right-angled triangle to secure the breastplate. It is ideal for the nail feet to protrude 1-2MM from the leather during use. Pass it through the leather hole in the connector, with the bottom on the flesh side of the leather, and then move the rivet cap onto the nail foot. Hold the rivet installation tool and leather/anvil vertically and strike with a hammer. The entire installation process of the rivet can be completed with multiple gentle hammering strokes, or it can be hammered lightly once and then hammered hard again. This is a matter of personal preference, and you will find a way that feels and feels comfortable to you as you practice. On the nail tail of a single-sided rivet, you can see through the nail hole that the nail body has been flattened to stabilize the nail cover. Tips: When installing rivets like the ones above, if you can't buy the right tools, just use a hammer and a hard surface like brick or slate. However, the finished product may not be the prettiest (you probably Will leave marks on the leather), be careful with your fingers when handling. FAQ

This common flaw is that the rivet legs used are too long. The leather material does not have enough support to make the rivets vertical, which will cause the rivets to be squeezed at an angle, causing the connected leather to tilt. . Such a piece may not look beautiful nor is it the strongest structural connection, but if the force used in combination with hammering is sufficient, the rivet should not separate and still be usable. Four-button installation

There are many colors and shapes of four-button buckles on the market. Four-button buckles can provide a relatively simple fastening solution, especially This is when the leather strip and leather strip buckle appear inappropriate. The installation holes of the four-button buckle do not need to be as compliant with the requirements of the rivet buckle, but it is best not to be too large. If it is too large, the buckle feet will be deformed, which will cause the male buckle cover or the female buckle to become loose. The buckle cover is not fastened tightly. Ideally, the buckle feet should protrude 1-2MM from the leather surface.When using it on leather that is too thick, you can thin the leather around the buttonhole so that it can be used. Place the outer buckle cover on the concave anvil, place the leather surface down on the buckle, and then place the female buckle part of the outer buckle on the protruding part of the buckle cover. Place the installation tool firmly into the hole, hold the installation tool perpendicular to the leather surface/anvil and gently hammer it to make the buckle feet snap back to the outer buckle cover. Place the lower buckle of the four-button buckle on the anvil surface, pass the lower leather surface through the lower buckle foot, with the leather surface and flesh side facing down, and then pass the other part of the lower buckle through the lower buckle foot, and do the same as above. Tips: When installing, it is best to hammer lightly several times and lift the installation tool from time to time to check the status of the nail feet and buckle cover instead of doing it in two attempts. It is best to roll the buckle feet back tightly against the buckle cover, but in actual operation, the buckle feet are easy to fall to one side, or the buckle feet are deformed or bifurcated, especially when the installation tool is not so vertical or the hammering belt is at a slight angle. occurs. Air hole installation

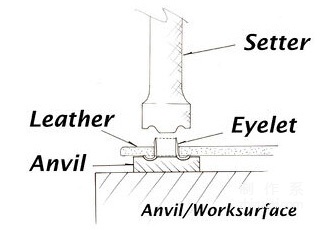

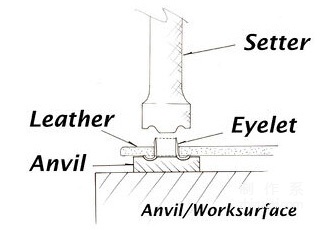

City Air holes are available in various shapes and sizes, and their main function is to strengthen the leather at the holes. The air holes prevent deformation and wear, especially when the perforations are subjected to some kind of tension. Examples include connecting forearm armor with leather cords or attaching sleeves to a blouse. Select the appropriate air hole size according to the size of the string, and also pay attention to the buckle feet, which should preferably protrude 2-3MM from the leather surface before they can be installed securely. The more compact the punch size and pore size are, the better, especially for thin leather that is easily deformed. The main reason is because the hammering surface only bends back a short distance. If the bending is too close to the edge of the hole, the air hole is likely to be pulled out. There are several small spacers that can alleviate this problem, and are best used to ensure firmness when using good leather. With the leather side facing out, insert the air holes through the leather. Place the vent on the mounting base and, if using shims, place the shims over the protruding vent feet. Hold the installation tool perpendicular to the leather surface/anvil and use a firm hammer blow to rotate the buckle foot onto the leather surface or gasket. Different sizes of pores and protruding lengths of pore legs require different hammering forces. Therefore, it is best to hammer lightly first to note the feeling, and then complete the installation in one go. Belt buckle installation

Two points that you need to pay attention to when installing a belt buckle are: one is to ensure that there is enough space for the pole in the middle of the belt head, and the other is the total width of the rivet. If the space is too large, the belt head will be loose. Although it won't fall off, it is quite annoying. If it is too tight, it will be awkward to move the pole, and installing rivets is also a problem, so it is best to operate with caution. The simple operation method is to gently fold the leather, leaving enough for the belt buckle Pass the space, place marks on both sides of the folded belt and lay the leather flat. These marks are the starting points of the buckle. There are special tools available for making belt buckles, or you can punch and cut them with regular holes. Use a leather knife to do the work. Punch two holes of the same size at the beginning and end marks you just marked, or slightly larger than the buckle, and then use a small ruler or bare hands to cut, if you are not afraid of hurting your fingers. It is best to go back and forth gently. Make a few light cuts to avoid cutting too hard. Another tip is to only cut the hole to the middle of the belt buckle hole. This can reduce the occurrence of overcutting as shown in the picture below. The two rivet holes can be 10 further away from the buckle hole. Mark at -15MM. When installing a 3/4-inch belt buckle on 3MM leather, approximately 45MM of space is needed between the rivet holes. If you have several belt buckles of the same size that need to be installed, it is best to make a paper pattern or Leather samples, so as not to measure them one by one. If the buckle does not bear a large load, usually one rivet can stabilize the buckle. For example, when making buckles, or armor, because the strength will vary from several leather strips and buckles Spread out. However, to increase strength or on wide leather strips, you can add rivets horizontally or vertically. If the leather for mounting the belt buckle is too thick, you can thin it from the end to the front of the first rivet hole. This will definitely Weakens the leather, so don't shave more.

HardwareRivets

Whenever possible, it is best to install rivets on a flat metal surface like an anvil. Use a small 21-pound anvil on your work desk or chair, or even place an iron plate on top of the bricks (is it so difficult to get marble? I'm dizzy). Unless the anvil and mounting surface are attached, its a good idea to put a pad between the anvil (or brick) and the work surface to prevent vibrations that could cause the object to bounce and slide. How to install rivets

Whenever possible, it is best to install rivets on a flat metal surface like an anvil. Use a small 21-pound anvil on your work desk or chair, or even place an iron plate on top of the bricks (is it so difficult to get marble? I'm dizzy). Unless the anvil and mounting surface are attached, its a good idea to put a pad between the anvil (or brick) and the work surface to prevent vibrations that could cause the object to bounce and slide. How to install rivets

Quick-install rivets< p style="text-align: center;">

Quick-install rivets< p style="text-align: center;">