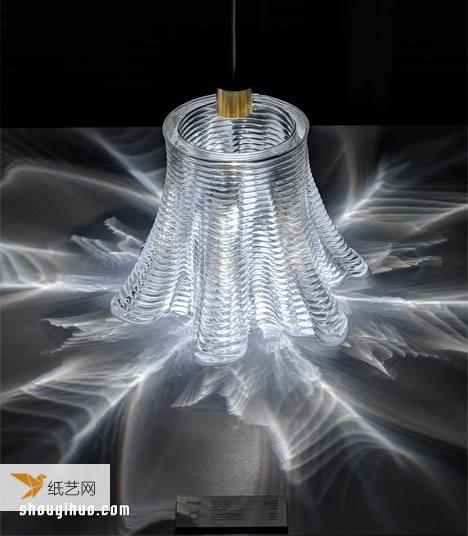

Using glass 3D printing technology to create glass handicrafts at thousands of degrees high temperature

Using glass 3D printing technology to create glass handicrafts at thousands of degrees high temperature

Previous glass items required heating, shaping, and blowing. There are many tedious processes such as coloring and cooling. If you don't have the ability, it will be difficult to create good results in the glass world. However, recently the mediated matter research team of the MIT Media Laboratory and the Glass Laboratory have joined hands.

Successfully developed a 3D three-dimensional printing method for glass, transforming the 3D printer into a container similar to a kiln. It can be heated, shaped, and cooled directly in the printer, so even very stupid people can create in the world of glass A world.

Glass 3D printing technology is mainly based on the concept of a double-layer heating furnace. The main task of the upper layer above the 3D printer is to heat the glass.

Use about 1037 degrees to dissolve the glass into a liquid state , and then use the same high-temperature resistant aluminum silicate zirconia ceramic nozzle to spray it out to shape the liquid glass into the desired shape layer by layer. The task of the lower layer is to gradually cool down to prevent the glass from being damaged due to excessive temperature changes. Shattered.